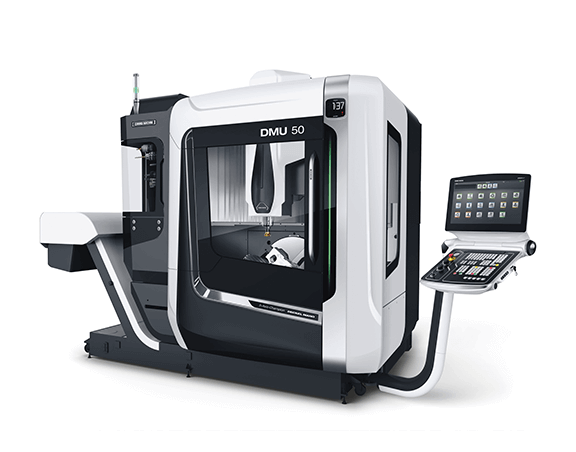

The DMU monoblock and Duoblock 5-axis universal machining centers allow the highest machining performance and part accuracy. These machines come standard with patented tool changer, rigid bed, and optional 5-axes simultaneous machining. The DMG I-series vertical machining centers are designed with a compact design and high-speed spindles, specifically for mass production machining.ĭMG Mori Milltap machines are compact, high productive machining centers. These machines come standard with high-speed spindles, automatic pallet changers, and more.

#Dmg mori filtration series#

The NV series of vertical mills are designed for die and mold machining. These machines come standard with high precision machining, making it ideal for any industry, producing a variety of workpieces. The NVX Series machines offer the highest accuracy worldwide. These machines come standard with 20,000 RPM spindle, and tool magazines of up to 120 pockets. The DMC-V is a powerful 3-axis machine which includes ball screw nuts and guide ways in all linear axes, with high precision.

These machines come standard with a 12,000 RPM inline spindle, and C-frame designed with a rigid Y-axis. The CMX-V series milling machines are versatile, handling a wide range of workpieces for all kinds of fields.

#Dmg mori filtration full#

Manufacturer: DMG Mori Model: NHX 4000 Spindle Taper: CAT40 Taper Control: M730UM DMG Mori Control With Celos Software, MAPPS System, ERGOline Touch Available January 2021 M730UM DMG Mori Control With Celos Software, MAPPS System, ERGOline Touch, 15,000RPM 40HP CAT40 Taper Spindle, Full 4th Axis Capable with Direct Drive Motor on B ?/p> Inquire Nowįeatures of machine Features of machine Max. DMG Mori equipment moreMachinioĢ016 DMG Mori Seiki NHX4000. We run 3 shifts in most areas, so any time saved is quite valuable. Even when planned, it takes quite a while to get in, swap out the individual plates, and get back out. One of the big sources of downtime is changing the drum filter. Sep 28, 2014We use almost exclusively Makino A51/A61 CNCs.

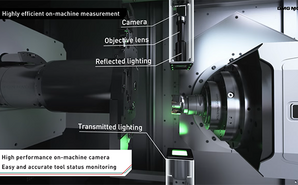

Quick Change Drum Filter?Practical Machinist.The integration of a turning center and a machining center achieves high performance, which enables efficient process integration for highmix lowvolume production as well as mass production. The NT series models are allrounders capable of highefficient machining of complexshaped workpieces for the aircraft, medical equipment, automotive, die mold and precision equipment fields. or less Long: bigger than the above ?The options table shows the general options when using coolant. or less in length, bundles of chips A 40 mm A 1.6 in. Scraper type+drum filter type A Scraper type+ ^ drum filter type Hinge type + drum filter type ?Chip size guidelines Short: chips 50 mm 2.0 in. NH 5000 DCGDMG MORIPDF CatalogsTechnical.

0 kommentar(er)

0 kommentar(er)